Types Of Heat Exchangers A Heating And AC Repair Company May Install In Your HVAC System Or Furnace | Fort Worth, TX

Heating and air conditioning systems use heat exchangers to transfer heat energy efficiently. Has your heat exchanger cracked? Is it damaged? Then you might be shopping for a new one. However, heat exchangers aren’t cheap. Therefore, you must ensure that you purchase the right component. There are many types of heat exchangers in the market today. Hence, you should enlist the assistance of a heating and AC repair company to choose the right component. Generally, heat exchangers are of 5 types, and various HVAC systems are fitted with different heat exchangers. Every heat exchanger has its unique application characteristics, merits, and demerits. Below are the main types of heat exchangers.

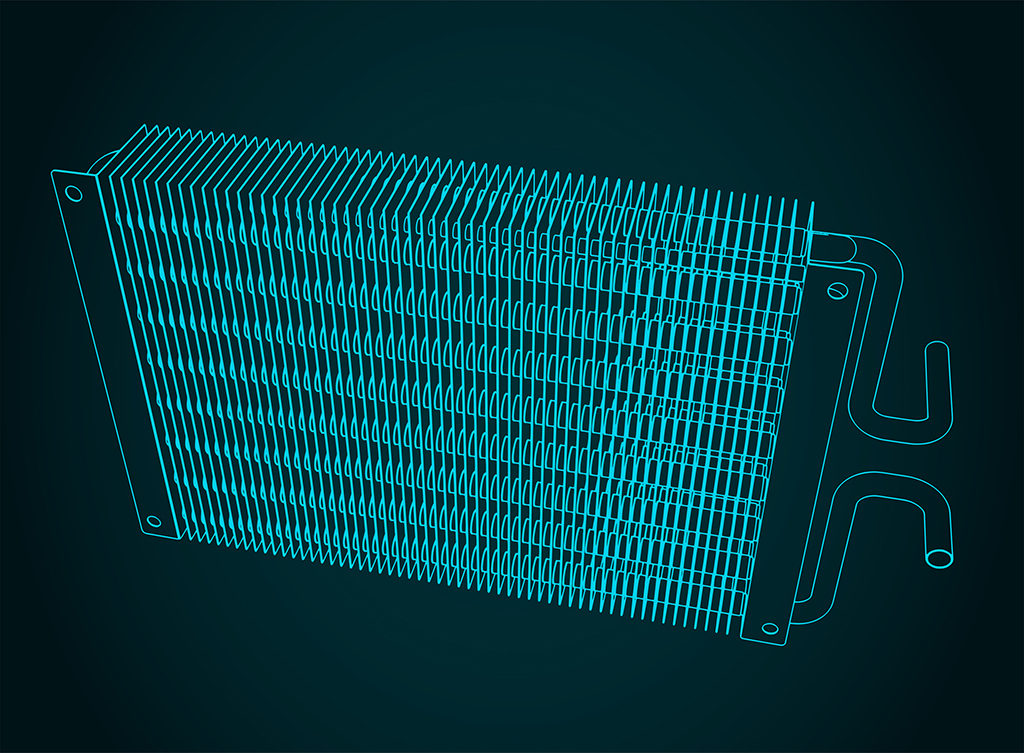

Finned-Tube Heat Exchanger

These are the commonest type of heat exchangers and are installed in most HVAC systems. Finned-tube heat exchangers can be found in commercial and residential heating and air conditioning units. They exchange heat energy between a refrigerant and the air. The finned-tube heat exchanging units can be found in ceiling cassette, wall-mounted, ceiling ducted, floor standing, window, air handling, fan coil, and through-the-wall units.

The finned-tube heat exchangers are commonly found in multi-split air conditioners, split air conditioning systems, heat pumps, window AC units, and variable refrigerant flow air conditioners. However, this doesn’t mean you purchase a finned-tube heat exchanger because you own either of these units. Rather, you should enlist the help of your heating and AC repair company to determine the size and type of the heat exchanger.

These heat exchangers are normally made from copper and aluminum. The fins of the finned-tube heat exchangers are made from aluminum sheets (thin), while their tubes are made from copper. The two products are good heat conductors. Finned-tube heat exchangers are usually coated in homes or residential spaces with an anti-corrosion substance layer. That’s why the fins are blue-colored. The treated finned-tube heat-exchanging units are also called hydrophilic finned-tube heat-exchanging units.

Some HVAC components, such as the outdoor unit, are constantly exposed to weather and other elements that might contribute to corrosion. Thus, they will require routine maintenance from a reliable heating and AC repair company. Fortunately, the coated layer in the finned-tube heat exchangers protects it from such, meaning they can last longer. Further, the fins look better.

On the other hand, commercial HVAC systems’ finned tube heat exchangers, like the air handling and fan coil units, are normally not coated with a layer of anti-corrosion substances. This is because they are normally concealed within the HVAC unit. Such finned-tube heat exchanging units are silver-colored due to the nature of aluminum.

These heat exchangers are of varying shapes and forms. However, the most common shape is u-shaped. This can be seen within the outdoors of your split AC unit. At times, they are arranged like an A that can be seen within the outdoor unit of an air source heat pump. This heat exchanger is easy for the heating and AC repair company to install, service, and repair. Unfortunately, they are bulky. Thus, they cannot be used in compact heating and cooling systems like water-cooled variable refrigerant flow units.

Since the fins of this heat exchanger are very compact, they collect dust over time, although filters are installed before them. Hence, you should have routine maintenance offered by a heating and AC repair company. The most common issue with finned-tube heat exchanger HVAC systems is that copper tubing is prone to cracking, resulting in refrigerant leaks. Another issue with these units is dented fins. However, the technician can repair the fins using the fin comb and the cracks through brazing.

Brazed Plate Heat Exchangers

The other common type of heat exchanger is the brazed plate heat exchanger. It is commonly used in HVAC units that use water as a heat transfer medium. They are used for exchanging heat energy between the refrigerant and water. Brazed plate heat exchangers are commonly used in air-cooled and hybrid chillers, water-source heat pumps, and air-source heat pumps. Since not all such systems may have this heat exchanger, you should enlist a heating and AC repair company. They are made from copper and stainless steel. The plates of these heat exchangers are made from corrugated thin stainless-steel plates. A thin sheet of copper is installed in between.

Because they are covered in a closed-cell insulation layer to avoid condensation, most brazed plate heat exchangers have a black color. If the insulation were removed, the copper and stainless-steel materials would leave behind insulation that is both bronze and silver colored. Brazed plate heat exchangers for HVAC are substantially smaller than finned tube heat exchangers. Therefore, a heating and AC repair company can install them even in compact HVAC units. These heat exchangers have a rectangular shape with curved corners.

Since the heat exchanger’s plates are tightly packed, they are prone to blockages. A y-strainer is installed to capture dirt and water before reaching the heat exchanger to avoid frequent blockages. However, the filter mesh of this y-strainer should be finer than the heat exchanger. Otherwise, the process of filtration will not be effective. Unfortunately, repairing brazed plate heat exchangers is challenging even for an experienced heating and AC repair company. In most instances, a replacement is required as the repair is impossible. But it should be flushed if the water cannot flow via the brazed plate heat exchanging unit because of a blockage.

Thus, it is advised to install empty thermowell or service pockets in the pipe network to ensure future flushing maintenance tasks can be completed without requiring the removal of the pipe connections. Moreover, the inside of a brazed plate heat exchanger could crack. This is a problem as it could result in a refrigerant leak. Hence, it should be repaired immediately by a reliable heating and AC repair company. Remember, the refrigerant may pollute the water that is flowing. Water contamination is detrimental for applications involving hot water.

Shell-and-Tube Heat Exchanger

These heat exchangers are highly common for commercial heating and air conditioning systems rather than residential ones. Shell-and-tube heat exchangers can be found in chilled water systems. You’ll almost always find them in water-cooled chillers. These heat exchangers are normally made of low-carbon steel and copper. However, shell and tube heat exchanging units in the water-cooled chillers have several differing appearances.

These heat exchangers are black if used as evaporators since they are wrapped in a closed-cell insulation layer that prevents condensation. When used as condensers, shell-tube heat exchanging units have a beige or green paint. However, they may have other colors based on the building requirements. Hence, you must consult your heating and AC repair company when looking to replace yours. These heat-exchanging units have two flow patterns; counterflow and parallel flow. The flow can also be either 1, 2, or 3 passes.

Among all these, the 2-pass counterflow heat exchangers are the most common. They are also called counterflow or 2-pass chillers by heating and AC repair company professionals. The pressure drop and efficiency across these heat exchangers heavily rely on the number of passes. If an exchanger has more number of passes, then it will have a greater heat exchange. However, it will have a higher pressure drop. Also, shell-and-tube heat exchangers or water-cooled chillers could be categorized as dry or flooded.

For dry-type shell-and-tube heat exchangers, the coolant flows through the bed as water fills up and flows through a shell. On the other hand, the coolant fills up and flows through the shell as the water flows through tubing in flooded-type shell-and-tube heat exchangers. Low-capacity water-cooled chillers use dry-type shell-and-tube heat exchanging units. In contrast, most medium to large-capacity water-cooled chillers use the flooded-type shell-and-tube heat exchanger. Hence, your heating and AC repair company will install a replacement heat exchanger based on the capacity of the HVAC system.

Tube-in-Tube Heat Exchanger

Do you have a VRF HVAC system installed at your home? Then there is a high probability that it uses a tube-in-tube heat exchanger. These are small but highly efficient heat-exchanging units designed specifically for low-flow applications. Hence, they are common in water-cooled variable refrigerant flow (VRF) systems. However, you should confirm with your heating and AC repair company.

These heat-exchanging units are made from stainless steel and copper. The inner tubing comprises corrugated copper tubes, while the outer tubing is made from stainless steel tubes. They are also coated with a PVC material layer, making them appear black. These heat exchangers are also called coaxial tube heat exchangers. The water-cooled variable refrigerant flow systems are also compact. Therefore, a heating and AC repair company normally places them above the ceiling or within the cabinet. They also feature a compressor that produces cold refrigerant that helps in air conditioning. However, these units need condensing water for heat dissipation. Therefore, the heating and AC repair company must also install condenser pumps and cooling towers.

In water-cooled VRF HVAC systems, the refrigerant flows through the heat exchanger’s outer tube. At the same time, condenser water flows into the inner tubing made of corrugated copper. Similarly, these heat exchangers can flow coolant in counterflow or parallel patterns. Although these are rare because water-cooled VRF systems are uncommon, that doesn’t mean they aren’t available. If you own one, you should have regular maintenance from a reliable heating and AC repair company.

Plate Heat Exchanger

These heat exchangers are very common in HVAC systems for large-scale cooling applications. You are more likely to find them in use in chilled water systems. Plate heat exchangers are normally used for exchanging heat energy between two different chilled water sources. Plate heat exchangers are usually found in tall buildings where they are used for breaking chilled water pressure. However, you can call a heating and AC repair company to install or repair them in buildings with distinct cooling systems.

The pressure to operate the chilled water systems ranges from 10 to 12 bar. A heating and AC repair company can install the plate heat exchanging units on intermediate floors of a very tall structure if the water pressure exceeds 20 bar. Reducing the pressure to a level lower than 20 bar is necessary. When incorporated into a district cooling system, Plate heat exchangers can be located in structures without installed chillers. They acquire chilled water from a district cooling plant and use it in the plate heat exchangers, which function as chillers. At one end, the plate heat exchangers process the chilled water produced by the district cooling plant. In contrast, the plate heat exchangers cool the water recirculated throughout the building.

In most instances, the HVAC system plate heat exchangers are made from thin metal sheets of stainless steel. Therefore, they have a silver coloring. But when they appear black if used for cooled water as they are wrapped in a closed cell insulation layer. If the system uses panel insulation, then the exchanger can have a silver color. Most heating and air conditioning plate heater exchangers are largely based on the applications. You will mostly find them standalone units and not incorporated into the HVAC unit. The plate heat exchanging systems are highly similar to the brazed plate heat exchanging units but usually have additional gaskets. These aren’t bronze colored. They still require periodic maintenance from an experienced heating and AC repair company.

As you can see from the preceding, many heat exchangers are on the market today. However, each HVAC system uses a different kind, whether in terms of type, model, or even size. Hence, you should consult widely before purchasing a heat exchanger for your industrial, residential, or commercial HVAC system. Do you need a heat exchanger inspection, repair, or replacement? Contact us at One Hour Air Conditioning & Heating of Fort Worth for a professional service.

Check our most recent blog on this topic here.